TP 140 /33 Parallel Twin Screw extruders for WPC applications

TP 140 / 33 Parallel Twin Screw Extruders

|

|

|

|

|

|

Just try to find a wood-fiber plastic composite twin parallel extruder with the processing capabilities of a TP140-33. |

|

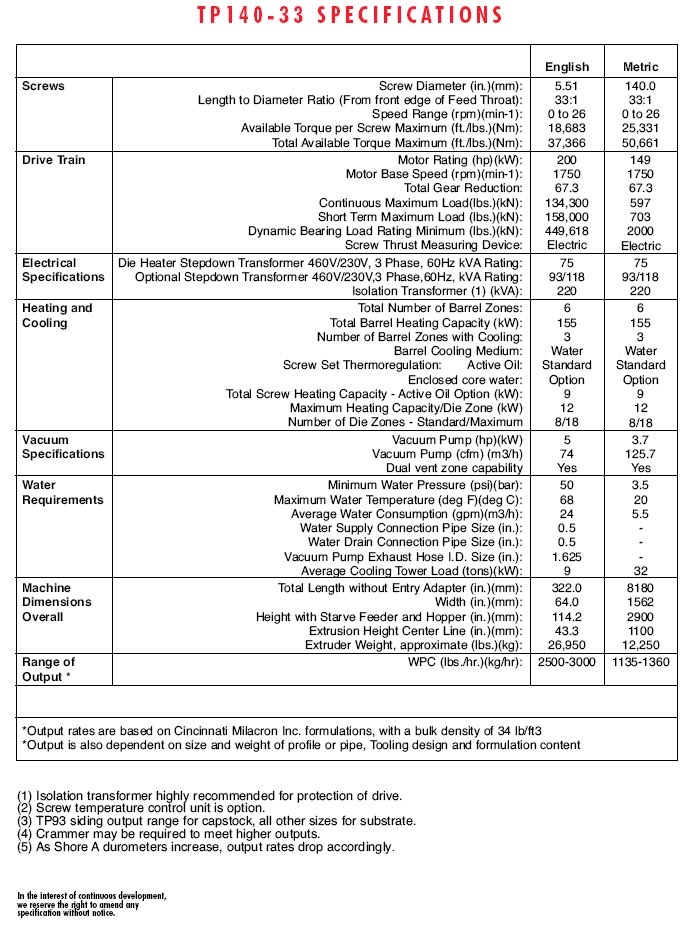

| For rates up to 2,500-3,000 lbs/hr, depending on profile. Application versatility: can extrude either solid or engineered profiles. Eisenbeiss four-shaft Torque Master gear box design providing greater torque capability and durability. Bimetallic barrel and tungsten-coated screws for longer wear life, ease in rebuilding and lower overall life cycle cost. Optional automatic vent cleaner, designed to keep the vent stack clear of any wood-fiber build-up. Dual vacuum canisters for ease in clean out without scrapping product. Option for 33:1 l/D to optimize processing performance in wood-plastic composites: • Provides for longer residence and greater residual moisture removal. • Lower process temperatures over a longer time period to achieve final melt temperature. • Multiple vent capability with optimal distance between vents. Produces an optimal melt condition based on its treatment of the raw material in the process (conveying, melting, mixing,venting and pumping). Excellent conveying and devolatilization characteristics (deep flight channels, tight intermesh clearances, low RPM, positive displacement pumping). Can process pre-blended or pelletized wood-plastic composite compound, and regrind. Excellent for introduction of blowing agents for foamed extruded products with reduced density. Excellent dispersive characteristics for high quality color systems. High head pressure capabilities. The TP140-33 is part of a comprehensive extrusion technology product line that includes a complete range of parallel and conical counter-rotating twin screw extruders, co-rotating twin screw extruders (specifically for wood-fiber plastic composites), and single screw extruders to meet a broad range of application needs. |

|

|

|

Downoad the PDF TP Series Specification Sheet Downoad the PDF TP Series Specification Sheet |

|